Going In Circles? Good!

All Work

JUNE 12, 2024

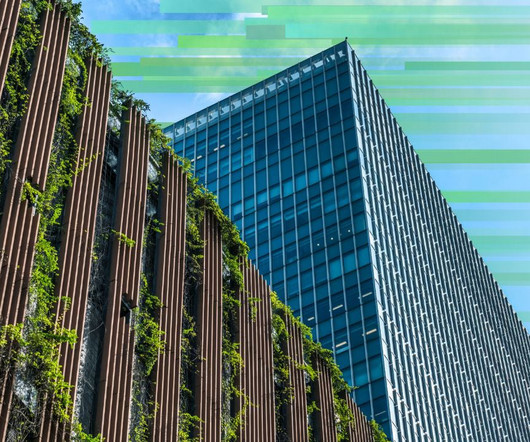

Architects and designers are increasingly prioritizing sustainability, focusing on low-VOC, recycled materials, and reducing embodied carbon through reuse and modular construction. Designers encourage product manufacturers to include recycled content, lower VOCs, streamline manufacturing processes and track embodied carbon.

Let's personalize your content