Visitor Compliance for Manufacturing: What is it exactly?

The Receptionist

JULY 27, 2023

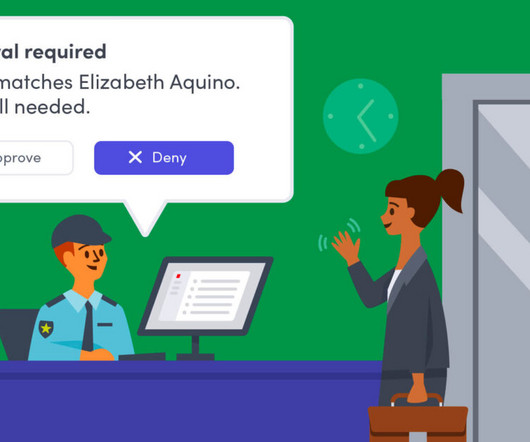

If you work in manufacturing, you’re no stranger to compliance. Understanding Visitor Compliance for Manufacturers Manufacturing visitor compliance broadly refers to adhering to legal and safety regulations when managing visitor access within your facility. One such case is how to handle your facility’s visitors.

Let's personalize your content